For this I used a dark red krylon fusion. this will protect the foam from the chemicals in the spray paint.Īfter a few coats of Plasti-dip, the foma is ready for a base color. I used Plasti-dip, a rubber spray, on all of my foam surfaces. You can use something as simple as Elmer's glue as a sealant. To prevent this melting from happening, you must first seal the foam. The surface of the foam will melt if you do this. Foam cannot be painted with aerosol spray paint. First disassemble, then it's paint time.Īll of my foam seams were smoother over with latex caulk. crimson! Of course it's not as simple as just painting it red. Since I am a Crimson Fist, the power fist needs to be.you guessed it. and all the necessary guides for the cables were also printed integral in each panel.īody work complete, it's time for paint.

WARHAMMER 3D PRINT FILES REGISTRATION

Notches and registration marks were added to make certain the panels align as intended during assembly. Then I added support ribs throughout the panel to give it strength.

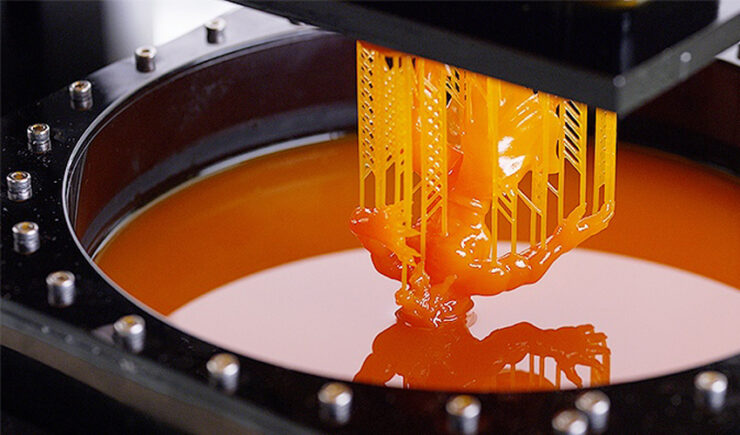

Each panel is printed flat, and has a thin outer skin. Second, I stole some inspiration from nature and modeled each panel after insect wings. First, I broke each finger segment into 4 separate panels that could be printed flat, and assembled after printing. I spent more time modeling this thing than I did in any other one step in my costumes creation, by far. The flaw was in my 3D model so I had to go back into design mode and gut my design. My test rig taught me that the elastic bands just weren't enough to support the weight of the fingers. As it turns out, weight became a big issue. The tests were mostly successful, but I did run into trouble.

It was complete enough that I could begin testing. I began printing.Īfter a while.a long while. Satisfied with my design and confident all the joints would fit together and move freely. I exported my STL files and fired up the printer. I simply scaled each one to created the different sizes of each finger. It is also worth noting that all the fingers are identical. By pulling these strings the Power Fist's fingers would curl over, and fold in on themselves thanks to some clever design work. Along the belly of the finger would be a pull-string that would be tied to my digits. This band would be held in place by rings built into the interior of each finger. Along the spine of each finger would be a taught elastic band that would hold the finger straight. Each segment would snap inside of the previous segment and terminate at the fingertip. My design consisted of 3 segments per finger. But after numerous version numbers and countless hours, I had what I thought was a solid design. My background in graphic design might have helped me to some degree, but the modeling process was a SLOW one, filled with mistakes and revisions to my original plan. There are MANY modeling softwares out there, but this program is free, and relatively simple to learn. Now, I needed to build a 3D model from scratch, one with multiple moving parts, no less.įor this process I used Google Sketchup. Up until this point, my 3D prints were all things downloaded from thingiverse. My experience with my printer thus far had taught me that those two concepts are not mutually exclusive in the world of 3D printing. Now that I had an the kinks worked out (at least it made sense in my head) I needed to transform my 2D scribblings into a 3D model that my printer could both understand, and produce. all pieces must fit together without the use of visible hardware (see goal 1) My goals: -stay as close to the game models as possible -make all fingers articulate, realistically. this took a few days of deep thinking and planning, but in general, below is a list of what I was hoping to accomplish. I fixed it in my mind that the working parts would be made from 3D printed plastic and got to sketching. My wife had recently bought me a Solidoodle2 3D-printer for Christmas, and I was actively looking for projects make with my new toy. I simply could not fathom a way to create a working foam finger that would be durable, and stay as close to the game model as I had envisioned. Foam is a great medium, but things like wall thickness, and a lack of real structural stability make it difficult to creating mechanical parts with it. It looks great, but after some thought, I decided to take things in another direction. MY PLAN Henrick made his powerfist out of foam. Henrik is a huge inspiration for me and my build, and a swell guy in general. INSPIRATION Inspiration struck me after seeing a super talented fella by the name of Henrik Pilerud, make his own Power Fist.

0 kommentar(er)

0 kommentar(er)